Plastic bag barcode laminate gift craft paper bags press flexo Printing machine price for paper cups

Introduce sensitization resin as flexible printing plate. It is a kind of ideal printing equipment for producing paper packing bag for good, supermarket handbag, vest bag and clothes bag,etc.Printing materials as following:

Category:

Keyword :

Product details

Introduction

Introduce sensitization resin as flexible printing plate. It is a kind of ideal printing equipment for producing paper packing bag for good, supermarket handbag, vest bag and clothes bag,etc.Printing materials as following:

1.Polyethylene, polyethylene plastic film printing

2.Bag(packing bag for food, supermarket handbag, vest bag and clothes bag printing

3.Roller paper and craft paper printing

4.Pp woven bag , pvc film, bopp film, printing

5.Laminated bag rolling printing

6.Non woven rolling printing

7.Rice bag pp woven printing

8.Paper printing

Note:Different printing material , machine some parts design different. Pls kindly show Printing material when inquiry.

Main Features & Advantages

1.Machine form: use big gear drive and register color the color more accurate.

2.The structure is compact.The parts of the machine can interchanges standardization and easy to get.And we choose low abrasion design.

3.The printing cylinder is really simple.It can save more time and cost less.

4.The printing pressure is smaller.It can decrease the waste and make service life longer.

5.Print many kinds of material include various thin film rolls.

6.Adopt high quality ceramic anilox roller to increase the printing effect.

7.Adopts imported electric appliances to make the electric circuit control stability and safety.

8.Machine frame:75MM thick iron cast.No vibration at high speed and have a long service life.

Technical Parameter

|

Model |

NXC6-600 |

NXC6-800 |

NXC6-1000 |

NXC6-1200 |

NXC6-1400 |

NXC6-1600 |

|

Max. Material width |

600mm |

800mm |

1000mm |

1200mm |

1400mm |

1600mm |

|

Max. Printing width |

560mm |

760mm |

960mm |

1160mm |

1360mm |

1560mm |

|

Printing color |

6+0, 5+1, 4+2, 3+3 |

|||||

|

Printing length |

191-1200mm |

|||||

|

Printing plate lifting system |

Automatic Hydraulic press control |

|||||

|

Mechanical speed |

100m/min |

|||||

|

Max.running speed |

80m/min |

|||||

|

Anilox roller |

Metal: 100-300LPI Or Ceramic anilx roller(200-1000LPI), single doctor blade |

|||||

|

Register precision |

Longitude:±0.25mm Transverse:±0.25mm |

|||||

|

Rewinder/Unwinder Diameter |

ø 1000mm |

|||||

|

Electrical header |

14KW |

16KW |

20KW |

22KW |

24KW |

26KW |

|

Weight |

4500Kg |

4750Kg |

5600Kg |

5250 Kg |

5500Kg |

5750Kg |

|

Master power |

25KW |

27KW |

34KW |

37KW |

43KW |

47KW |

|

Dimension (L×W×H) |

5.0×2.0 ×3.2(m) |

5.0×2.2×3.2(m) |

5.0×2.4×3.2(m) |

5.0×2.6×3.2(m) |

5.0×2.8×3.2(m) |

5.0m×3.0m×3.2m |

|

Bearing |

Japan(NSK) |

|||||

|

Unilateral bearing |

ASNU (Germany) |

|||||

|

Machine Also can made as client requirement. If you need other width Size or high speed machine , pls kindly contact us directly. |

||||||

Optional Parts

1.Various size of Printing cylinder

2.Double unwinder/rewinder

3.Automatic pneumatic loading

4.Automatic pneumatic unloading

5.Crane:Manual or electric

6.Ceramic Anilox Roller

Details Images:

Unwinder and rewinder part:

Manual single unwinder and rewinder

.png)

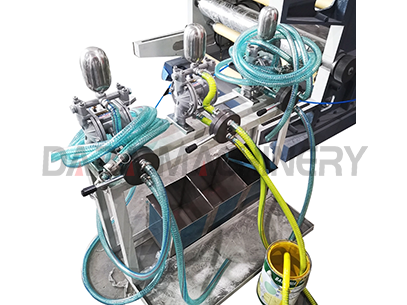

Printing Part:

With 6 sets ink pumps , it is circulating , the ink will never dry.

With single doctor blade and metal anilox roller.

*Plate roller is Hexagon design with Chrome.

.jpg)

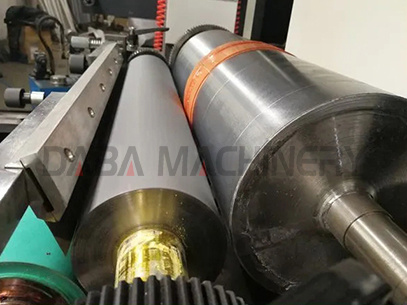

Transferring Part:

With helical gear : little noise while machine is running.

With helical gear : good register and the final roll will be accurate.

Drying Part:

The oven length is 1.5 meters , all printing group is heat wind circulating.

Printed Samples:

.jpg)

Related products

Message