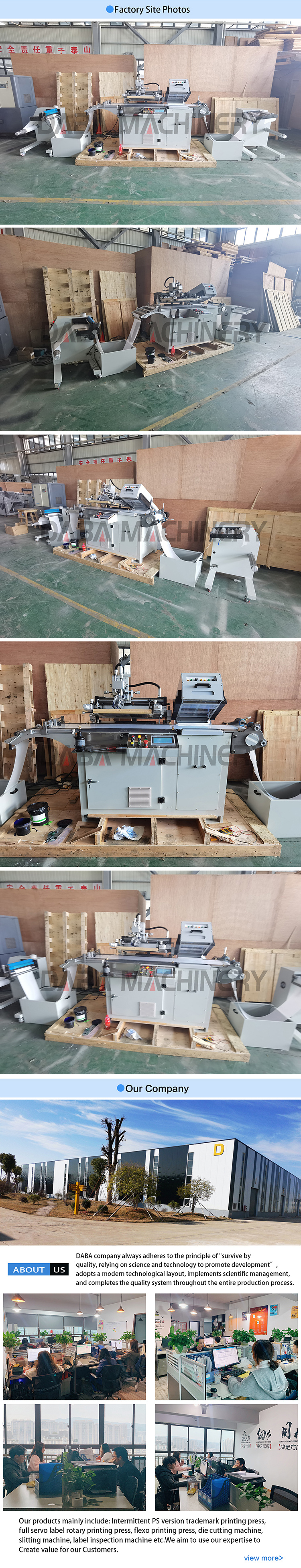

DBSY-350 screen printing

DBSY-320FulAutomatic Silk ScreenPrintingmachine This is a machine of simple operation and high quality

Category:

Keyword :

screen printing

DBSY-320FulAutomatic Silk ScreenPrintingmachine This is a machine of simple operation and high quality High Quality乙Quick Printi

Product details

Product Introduction

As an important production equipment, printing presses are widely used in many industries.

Our company's printing machine products have stable, reliable, efficient, and energy-saving characteristics, suitable for mass production, and can meet the needs of customers for rapid production.

At the same time, our products are suitable for various materials, including paper, plastic film, and metal sheet, with corresponding characteristics also varying.

For example, for paper printing, our products have the characteristics of bright colors and high clarity, greatly improving the quality of printed products.

In addition, our company's printing machine products have advantages such as high durability and easy maintenance, which can greatly reduce customer usage costs.

Based on the above characteristics, our printing machine products are highly welcomed and favored by domestic and foreign customers, making them the best choice for your printing production.

1.lt is suitable for printing products such as scratching silver and cosmeticlabels, as well as overprinting and glazing of printed labels.

2. Printing materials in roll, self-adhesive paper, PVC, PET, PP, PC, PEBOPP, and other printing materials.

3. Japan Yaskawa servo motor to ensure precision and stability.

4. English touch screen control panel

5. The user-friendly touch screen control panelfor maximum operationconvenience.

6. The print head rise and fall vertically for convenient access to screenand squeegee.

7. The squeegee and flood bar printing angle and pressure is adjustableto fit different printing tasks.

8. Using Panasonic high-precision follow-up electric eye, 3 colors, suitablefor different materials and colors, the secondary color registration is accurate.

9. Aluminum alloy machine frame ensures high stability and no deformation.

10. Rust proof painting has been applied on the machine to prevent itfrom getting rust.

11. Castor wheels are installed on machine for easy movement.

12. Unwinding and rewinding units use air shaft, easy loading & unloadingof film roll and prevent slippage.

13. The pitch feeding roller is driven by servo motor, ensuring exact lengthfilm feeding as per setting at all times.

14. Feeding and winding mechanism utilizes advanced sonar sensor foraccurately sensing transparent and non-transparent film.

15. Precision linear motion quides are used on horizontal slideway forextremely smooth and stable printing head stroke.

16. The machine is equipped with 2 sets of UV lamp to efficiently andquickly dry the ink.

17. High-quality aluminum alloy screen frame, convenient for printing work.

|

Product Model |

DBSY-350 |

DBSY-420 |

|

Max. Substrate Width |

320mm |

420mm |

|

Max. Printing Area |

350*400mm |

400*500mm |

|

Max. Printing Speed |

1000~9000times/hour |

1000~9000times/hour |

|

Screen Frame Size |

550*700mm |

550*800mm |

|

Printing Precision |

±0.20mm |

±0.20mm |

|

UV Dryer Power |

7.2KW |

7.2KW |

|

Max Unwinding Dia |

700mm |

700mm |

|

Max Rewinding Dia |

700mm |

700mm |

|

Dimension(L*W*H) |

4650*1100*1670mm |

4650*1200*1670mm |

|

Machine Weight |

About 2500KGS |

About 3000KGS |

1、Unwinding Unit 2、Unwinding Traction 3、Unwinding Induction Frame (including sensor)

4、Tracking Sensor (for registration) 5、Screen Printing Unit 6、UV Dryer (2units)

7、Rewinding Traction (Servo Motor) 8、Rewinding Induction Frame (Including Sensor)

9、Rewinding Unit 10、Operating Panel

Machine Detail

|

- Unwinding Unit 1. 3-inch diameter air shaft for loading substrate roll. 2. Adopt friction plate tension control. 3. Press belt with dust remova device 4. With metal unwinding induction frame, with a sensor or materarto automat calv reeos the paper. 5. With Auto Ending roll sensor, automatic induction of the material shortage and shutdown. 6. Electrostatic spray paint on the surface of the fuselage, no easy to rust. |

| - Printing Unit 1. Using Panasonic high-precision tracking electric eve, 3 colors. suitable for different materials and colors 2. The print head rise and fall vertically for convenient access to screen and squeegee. 3. The squeegee and flood bar printing angle and pressure is adjustable to fit different printing tasks. 4. Precision linear motion quides are used on horizontal slideway for extremely smooth and stable printing head stroke. 5. Equipped with 1 set of high-quality aluminum alloy screen frame. |

|

|

- Heating Oven 1. Equipped the oven with 2 UV lamps to dry the inK at high speed and etriciency 2. The power of each UV lamp is 3.8KW |

| -Traction Unit Feeding traction adopts Japanese Yaskawa servo motor control. |

|

|

- Rewinding Unit 1. 3-inch diameter air shaft for substrate rolls rewinamno. 2. Rewinding tension adopt motor control. 3. A metal rewinding induction frame with a sensor, automaticallv rewind the paper. |

Related products

Message