Product details

Introduction

Introduce sensitization resin as flexible printing plate. It is a kind of ideal printing equipment for producing paper packing bag for good, supermarket handbag, vest bag and clothes bag,etc. Printing materials as following: 1.Polyethylene, polyethylene plastic film printing 2.Bag(packing bag for food, supermarket handbag, vest bag and clothes bag printing 3.Roller paper and craft paper printing 4.Pp woven bag , pvc film, bopp film, printing 5.Laminated bag rolling printing 6.Non woven rolling printing 7.Rice bag pp woven printing 8.Paper printing

Note:Different printing material , machine some parts design different. Pls kindly show Printing material when inquiry.

Main Features & Advantages

1.After mounting the plate and registration,no longer need registration,improve yield.

2. Replacing 1 set of Plate Roller (unloaded 6pcs old roller,installed six new roller after tightening),only 20 Minute registration can be done by printing.

3. The machine first mount plate,pre-trapping function,to be completed in advance prepress trapping in shortest possible time.

4. Maximum production machine speed up 200m/min,registration accuracy ±15mm.

5. The overlay accuracy does not change during lifting running speed up or down.

6. With precision structural,easy operation,easy maintenance,high degree of automation and so on,one person can

operate.

7. HUICHUAN brand Servo motor for unwinding and rewind.

Technical Parameter

|

Model |

NXS6-600 |

NXS6-800 |

NXS6-1000 |

NXS6-1200 |

NXS6-1400 |

NXS6-1600 |

|

Max. Material width |

600mm |

800mm |

1000mm |

1200mm |

1400mm |

1600mm |

|

Max. Printing width |

560mm |

760mm |

960mm |

1160mm |

1360mm |

1560mm |

|

Printing color |

6 colors |

|||||

|

Printing length |

300-800mm |

|||||

|

Printing cylinder way |

Hydraulic control up and down |

|||||

|

Drive type |

Big center Roller drive |

|||||

|

Mechanical speed |

200m/min |

|||||

|

Max.running speed |

180m/min |

|||||

|

Anilox roller |

Ceramic anilox roller 6pcs: Shanghai murata brand 200-800LPI |

|||||

|

Tension system |

Automatic tension controller with magnetic powder brake |

|||||

|

EPC |

Web guide 1pc |

|||||

|

Register precision |

Longitudinal:±0.15mm crosswise:±0.15mm; |

|||||

|

Color register |

By motorized ( left and right, up and down) |

|||||

|

Unwind/rewind dia. |

Φ1000mm/Φ1200mm |

|||||

|

Unwind/rewind way |

Center unwind; Servo motor for rewind ; |

|||||

|

Printing way |

Full width on one side |

|||||

|

Dry system |

Electric heating |

|||||

|

PLC human touch screen |

1set, China famous Inovance brand |

|||||

|

Image inspect system |

1set, China famous kesai branad |

|||||

|

Machine power |

75KW |

78KW |

80KW |

90KW |

100KW |

110kw |

|

Machine size |

8×2.2×4.0m |

8×2.4×4.0m |

8×2.6×4.0m |

8×2.8×4.0m |

8×3×4.0m |

8×3.2×4.0m |

|

Machine Also can made as client requirement. If you need other width Size or high speed machine, pls kindly contact us directly. |

||||||

Optional Parts

|

1.Various size of Printing cylinder |

5.Half width Double sided printing |

|

2.Double unwinder/rewinder |

6.CI Drum with water Cooling System |

|

3.Automatic pneumatic loading |

7.Water cold cooling machine |

|

4.Automatic pneumatic unloading |

8.Shaftless for unwind |

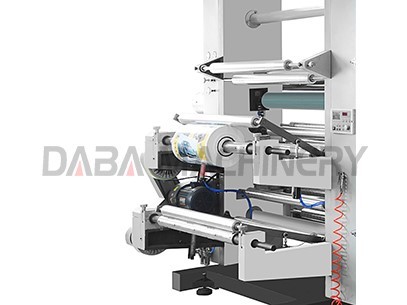

Details Images:

Register

Color register by motorized (left and right,up and down).

Unwinder and rewinder part:

Double manual unwinder and rewinder :the rewinder is with pressure roller.

PLC and camera

Printing part

Closed chamber: to make speed faster and the ink never splashs.

Ceramic anilox roller to make the finished samples more accurate.

Central roll : plate roller and traction roller and anilox roller on the central roll to work together.

Transferring part

Drying part:

The oven length is 3.7 meters , all printing part is heat wind circulating.

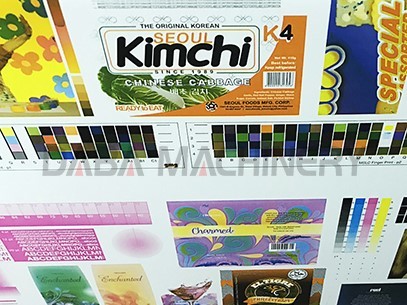

Printed Samples:

Related products

Message