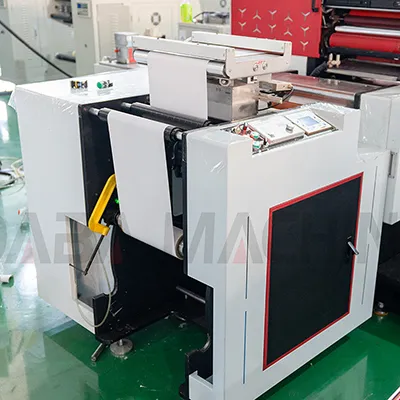

DBJY-320 450

The machine structure is simple, easy to operate, easy to maintain

Category:

Keyword :

High-efficiency

Stable Tension

Product details

Intermittent Label Offset Printing Machine

Machine Overview

The Intermittent Label Offset Printing Machine is equipped with an advanced servo control system to ensure stable material clamping and precise positioning. It minimizes downtime when changing cylinders and meets the high-quality requirements for both short-run and long-run labels. It is ideal for achieving low-cost, high-quality label production.

Technical Specifications

| Specification | DBJY-320 |

|---|---|

| Maximum Material Width | 350 mm |

| Maximum Printing Width | 320 mm |

| Maximum Printing Length | 350 mm |

| Maximum Printing Speed | 50–180 RPM |

| Maximum Core Diameter | 1000 mm |

| Maximum Take-up Diameter | 1000 mm |

| Printing Colors | 6-color Offset + 1 Flexo/UV Coating/Hot Foiling |

| Power Supply | Three-phase 380V |

| Total Power | 55 kW (excluding UV) |

| Dimensions (LxWxH) | 12,500×1,700×1,800 mm |

| Machine Weight | Approx. 15,500 KG |

Core Features

- Servo Control System

- Ensures precise material registration, eliminating gear marks/ghost images.

- Each printing unit (total 28) is equipped with an independent servo motor for accurate color alignment at high speeds.

- Printing Units

- Heavy-duty offset units, equipped with 19 ink rollers and 4 alcohol dampening rollers.

- 12-inch touchscreen control panel, featuring a fast CPU for efficient operation.

- Quality Assurance

- Video inspection system for real-time registration adjustment.

- BST camera monitoring and quality inspection area.

- Flexibility & Options

- Optional inline hot foiling, flexo UV coating, die-cutting, and laminating units.

- Memory-based ink control system for repeat jobs.

Standard Configuration

| Component | Description |

|---|---|

| Unwinder Unit | Servo motor-driven, with automatic tension controller and 3-inch air shaft. |

| Component | Description |

|---|---|

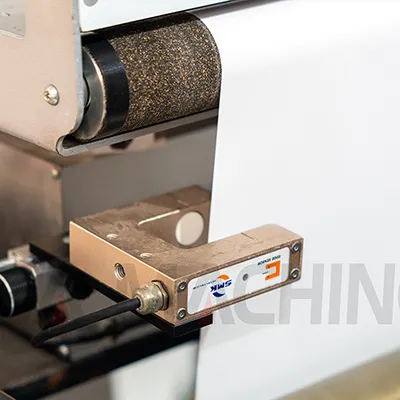

| Guide Device | SMK guide device for straight feeding. |

| Component | Description |

|---|---|

| Printing Stations | 12 sets of ink control adjustment; semi-rotary mode, equipped with 5 servo motors. |

| Component | Description |

|---|---|

| Winder Unit | Servo motor-driven, with automatic tension controller and 3-inch air shaft. |

| Component | Description |

|---|---|

| Control System | Inovance multi-axis control system (China) and Pro-Face 12.1-inch touchscreen (Japan). |

Optional Configuration

| Component | Description |

|---|---|

| Hot Foiling Unit | Inline hot foiling application, with UV dryer, for decorative effects. |

| Component | Description |

|---|---|

| Rotary Die-Cutting | 176T magnetic cylinder for economical tool change. |

| Component | Description |

|---|---|

| Flexo UV Coating | Spot/full UV coating, for enhanced visual effects. |

| Component | Description |

|---|---|

| Lamination/Slitting Unit | Label lamination/slitting process. |

| Component | Description |

|---|---|

| Silkscreen Printing Unit | Thick ink layer, for embossed texture. |

Technical Details

- Servo Motors: 43 (Innovate Control Systems, China) for precise motion control.

- Cameras: BST camera system (Germany) for real-time quality inspection.

- Alcohol Dampening: System supplied by Beijing for consistent ink transfer.

Applications

Suitable for industries requiring high-speed, high-quality label production, such as:

- Packaging

- Pharmaceuticals

- Food & Beverage

- Cosmetics

Related products

Message